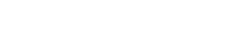

UNIPRIME PKW

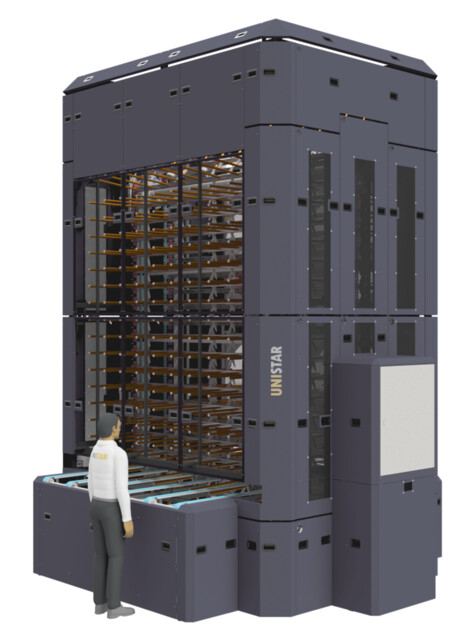

The ventilation chamber is a unit that can be used in the production plants manufacturing panels and elements made of foamed polyethylene. This allows to speed up the processes of gas exchange and cooling of the product, thus significantly reducing the total time of its seasoning. The chamber has 40 working shelves, 36 of which are active simultaneously, thus also providing an excellent production buffer. The input and output of the material are fully automated, and are carried out via input and output conveyor belts. For cooling, 4 large fans are evenly spaced in the working area. A state-of-the-art system of signalling the operating status as well as the possibility of process control thanks to the polycarbonate covers used significantly increase comfort and safety of use.

| Technical specification | |

| PKW-2800 | |

| Material type |

|

| Number of working shelves | 40 |

| Max plate size - width | 600 mm |

| Max plate size - length | 2800 mm |

| Max plate size - thickness | 110 mm |

| Material input | automatic |

| Material receipt | automatic |

| Machine dimensions (L/W/H) |

3730 / 4205 / 5480 mm |

| Machine weight | 4800 kg |

| Electric power | 7500 W |