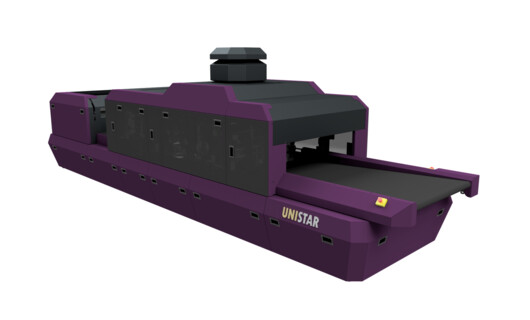

UNIBAG CZW

UNIBAG CZW is a machine used to produce bags made of polyethylene foam and PE bubble wrap with a capacity of up to 2 cycles per 1 s. In its basic version, the input material is a ribbon folded into half-sleeves. A stacking module has been used in the machine, allowing the bags produced to be put together in packs of up to 100 pieces with great accuracy. Such stacking enables easy packaging of the product and accurate control of the quantity of bags being produced.

Thanks to the modular design, the machine is easy to service and can be easily upgraded with new modules:

- longitudinal weld module,

- heat shrink packaging module.

The application of all the modules makes the machine fully automatic. The role of the operator is restricted to supplying the machine with the input material and receiving ready-made packages with bags.

Our highly innovative mechanical solutions make the machine less prone to failures, saving time spent on maintenance and focusing on production.

Thanks to all this, the production of plastic bags has never been easier.

| Technical specifications | |

| CZW-1000 | |

| Type of input material |

|

| Maximum material width |

500/1000* mm *(half-sleeve) |

| Input material thickness | 0,8 - 3 mm |

| Maximum bag size | |

| Input material density | 15 - 35 kg/m3 |

| Cycles per 1 s | 2 |

| Machine dimensions l/w/h (basic version) | 7100/1860/2000 mm |

| Machine weight | 2250 kg |

| Power supply voltage | 400 V |

| Electrical power | 21,5 kW |

| Designed in accordance with |

The achinery directive EC 2006/42 The Low voltage directive EC 2014/35 |