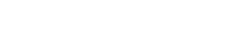

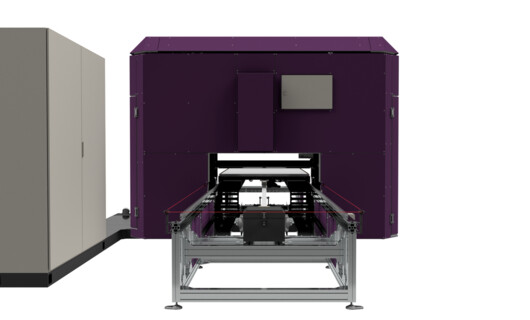

UNIPRIME CRH

UNIPRIME® CMZ it's only machine on the market to splitting and calibrating all types of foamed plastics like PE foam, PP, XPE, EVA and other more. There are installed two cutting units - one with band knife to split soft materials and second with tooth saw to split hard materials like polypropylene foam. This solution provides versatility in machine using.

Automatic vacuum table movement and automatic knife/saw height adjustment to cutted layer, makes machine automated, where operator work is only take off cutted sheets.

Machine may be expanded in additional industry robot for taking off cutted sheets, making this machine full automated and work costs limited to minimum.

|

Splitting hard foamed plastics |

|

Semi-automated work |

|

High cutting quality |

|

Minimum layer thickness - 1mm |

|

Splitting soft foamed plastics |

|

Full automated work* |

|

High cutting precision, +/-0,5mm thickness tollerance |

|

Constantly sharp knife due to automatic built-in sharpener |

| Technical specification | |||

| CRH-1200H2 | CRH-1200H10b | CRH-1200H10z | |

| Cutting units amount | 2 | 1 | 1 |

| Band knife type | band knife + tooth saw | band knife | tooth saw |

| Input sheet length (min / max) | 1000mm / 2800mm | 1000mm / 2800mm | 1000mm / 2800mm |

| Input sheet width (min / max) | 400mm / 1200mm | 400mm / 1200mm | 400mm / 1200mm |

| Input sheet thickness (min / max) | 10mm / 200mm | 10 / 1000mm | 10 / 1000mm |

| Max process speed | 300 mm/s | 300 mm/s | 300 mm/s |

| Installed electrical power (max) | 27,2 kW | 23,1 kW | 23,0 kW |