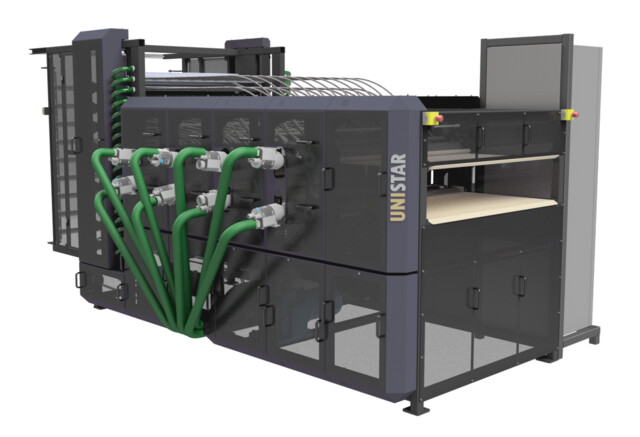

UNIPRIME LPS

UNIPRIME LPS is the best multilayer PE foam welding machine available on the market. In spite of its very compact design, the device allows for welding up to 9 layers of foam, which makes it possible to obtain a laminate up to 220mm thick! Additionally, UNISTAR's engineers have developed and implemented a compensation system that causes an even distribution of stresses in each layer. As a result, we were able to eliminate the negative effects of lamination, such as: bending of the plate "banana effect", deformation and whirling of the plate after delamination.

When creating our machines we care not only about the highest quality of the obtained product, but also about efficiency, user-friendliness and work safety. The solutions applied make it easier and faster to arm the machine with material and, above all, increase safety for the operator, who no longer has to put his hands between the shafts and push between the components.

UNIPRIME LPS is one example of a machine that sets a new standard in machinery design and combines quality, functionality and safety, thus eliminating the compromises that other companies have made so far.

| Parametry Techniczne | ||

| LPS-1400-5 | LPS-1400-9 | |

| Material type |

|

|

| Number of layers | 2 - 5 | 2 - 9 |

| Max size of input material - width | 1400 mm | 1400 mm |

| Max size of input material - thickness | 25 mm | 25 mm |

| Max size of output material - thickness | 125 mm | 225 mm |

| Machine dimensions (L/W/H) | 3700 / 2770 / 1600 mm | 5000 / 2400 / 2450 mm |

| Machine weight | 2600 kg | 3300 kg |

| Maximum power | 90 kW | 162 kW |

| Operating pressure | 5 bar | 5 bar |