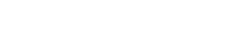

UNIPRIME CWP

This machine is designed to remove scrap from plates cut out on a slicing press. The automation of the process considerably improves and shortens the welding work for polyethylene foam packaging. The scrap is transferred to one place via a receiving conveyor and can be directly transferred to a collective waste transport system, which makes production even more automated. The machine has replaceable flat bars as a plate support element, the position of which can be configured in any way. More demanding products can be supported by a supporting plate that is individually tailored to the product. The ejector is in the form of a board with steel pins, the position and quantity of which can be easily and freely configured in a 15x15mm grid. Thus, one ejector matrix can be used for all products, while reducing costs for individual tools.

| Technical specification | |

| CWP-1200 | |

| Material type |

|

| Number of workstations | 1 |

| Max plate size - width | 1200 mm |

| Max plate size - lentgh | 800 mm |

| Machine dimensions (L/W/H) | 1925 / 2675 / 2370 mm |

| Machine weight | 1600 kg |

| Installed power | |

| Operating presure | 5 bar |

| Safety elements |

|